Understanding Directional Drilling and Its Applications

What is Directional Drilling?

Directional drilling is a sophisticated technique used to drill wells at multiple angles, rather than just vertically, to access subsurface resources. Unlike traditional vertical drilling, which limits access to resources directly beneath the drill site, directional drilling allows operators to reach targets that are miles away from the surface entry point. This flexibility has revolutionized industries like oil and gas, utility installation, and even environmental remediation.

The history of directional drilling dates back to the 1920s, but it wasn’t until the 1970s and 1980s that technological advancements, such as downhole motors and measurement-while-drilling (MWD) tools, made it a mainstream practice. Today, it is a cornerstone of modern drilling operations, enabling industries to maximize resource extraction while minimizing environmental impact.

The importance of directional drilling cannot be overstated. It has unlocked access to previously unreachable resources, reduced the need for multiple drilling sites, and paved the way for innovations in renewable energy and infrastructure development. Its versatility and efficiency make it an indispensable tool in modern engineering and energy production.

How Directional Drilling Works

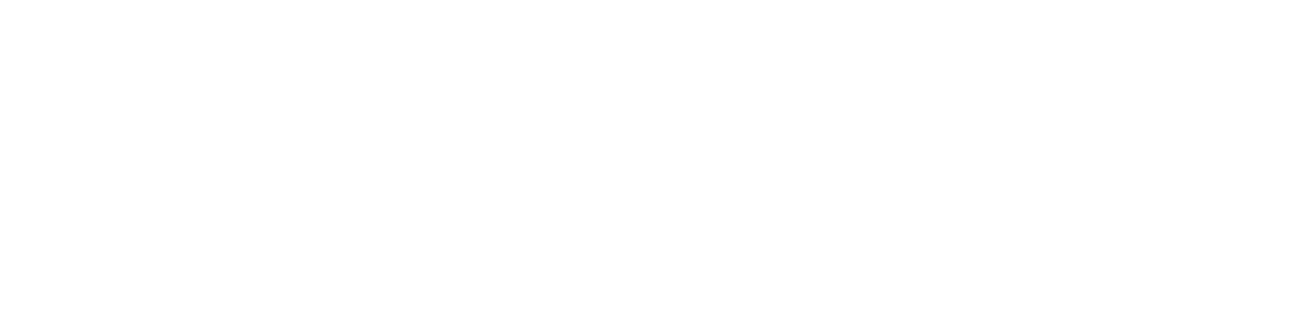

The process of directional drilling involves a combination of advanced tools, precise planning, and real-time monitoring. It begins with a surface entry point, where the drill bit is guided along a predetermined path to reach the target. Unlike vertical drilling, which relies on gravity to guide the drill bit, directional drilling uses specialized equipment to steer the drill in various directions.

Key tools in directional drilling include mud motors, which use hydraulic power to rotate the drill bit independently of the drill string, and rotary steerable systems, which allow for continuous steering without stopping the drilling process. Measurement-while-drilling (MWD) tools play a critical role by providing real-time data on the drill’s position, angle, and depth, ensuring precision and efficiency.

Geosteering is another essential component of directional drilling. This technique involves using geological data to adjust the drill’s trajectory in real time, ensuring it stays within the desired formation. By combining advanced technology with expert oversight, directional drilling achieves unparalleled accuracy, even in complex subsurface environments.

Types of Directional Drilling Techniques

Horizontal Drilling

Horizontal drilling is one of the most common and impactful forms of directional drilling. It involves drilling vertically to a certain depth and then gradually curving the wellbore to run horizontally within the target formation. This technique is particularly valuable in the oil and gas industry, where it allows operators to maximize contact with hydrocarbon-rich layers, significantly boosting production rates. Horizontal drilling has been instrumental in the development of shale gas and tight oil resources, making previously uneconomical reserves viable.

Multilateral Drilling

Multilateral drilling takes efficiency to the next level by allowing multiple wells to branch out from a single borehole. This technique reduces the need for additional surface infrastructure, lowering costs and minimizing environmental disruption. Multilateral drilling is especially useful in mature fields, where it can enhance recovery rates by accessing untapped pockets of resources.

Extended Reach Drilling (ERD)

Extended Reach Drilling (ERD) is designed to access reservoirs located far from the drilling site. By extending the horizontal reach of the wellbore, ERD enables operators to tap into resources beneath sensitive areas, such as urban developments or protected ecosystems, without disturbing the surface. This technique is widely used in offshore drilling, where it allows platforms to access multiple reservoirs from a single location.

Slant Drilling

Slant drilling involves drilling at an angle from the surface, making it ideal for accessing resources beneath obstacles like buildings, rivers, or other natural barriers. This technique is often used in urban or environmentally sensitive areas, where traditional vertical drilling is not feasible.

Key Applications of Directional Drilling

Oil and Gas Industry

Directional drilling has transformed the oil and gas industry by enabling the extraction of resources from complex and unconventional reservoirs. Techniques like horizontal drilling and hydraulic fracturing have unlocked vast reserves of shale gas and tight oil, driving energy production to new heights. Offshore drilling has also benefited from directional techniques, allowing operators to access multiple reservoirs from a single platform, reducing costs and environmental impact.

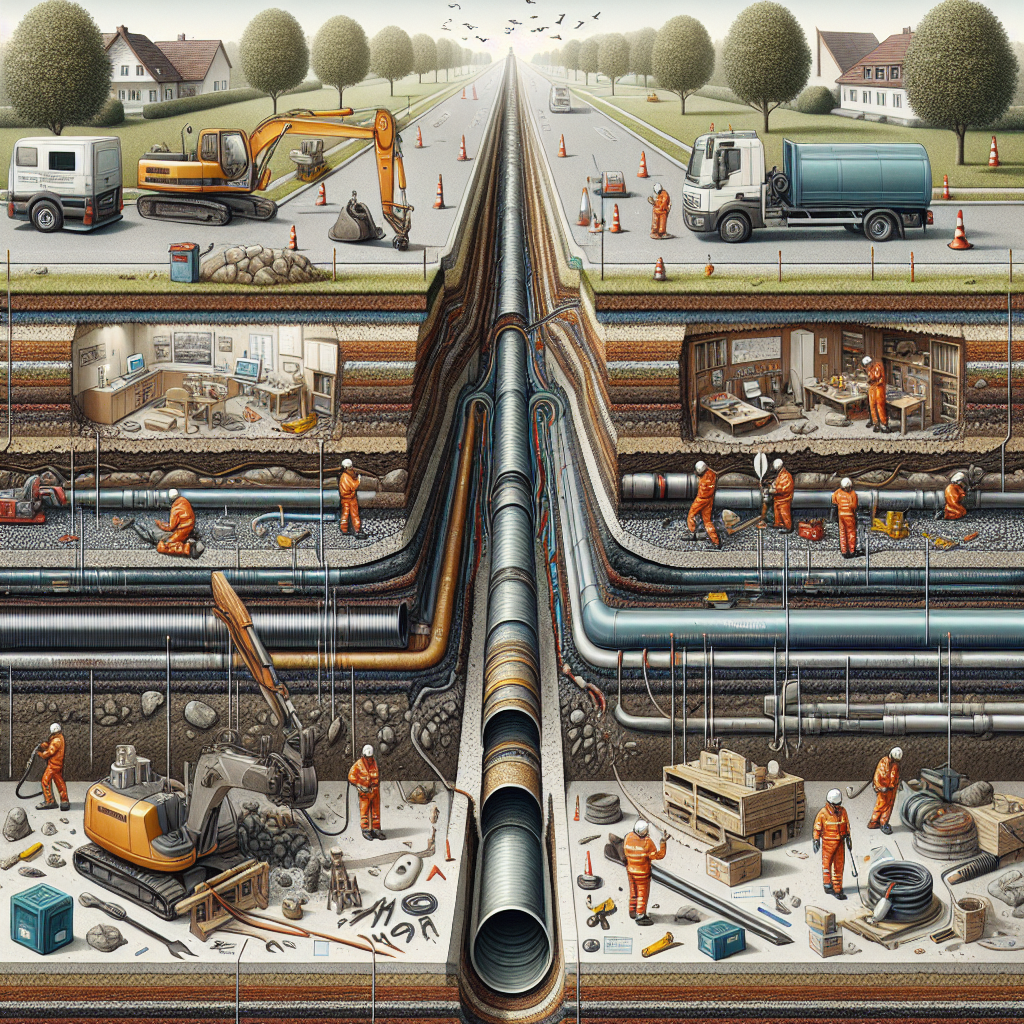

Utility Installation

In the utility sector, directional drilling is used to install underground pipelines, cables, and fiber optics with minimal surface disruption. This is particularly valuable in urban areas, where traditional trenching methods would cause significant disruption to roads and infrastructure. Directional drilling ensures that utilities can be installed quickly and efficiently, with minimal impact on the surrounding environment.

Geothermal Energy

The renewable energy sector has also embraced directional drilling, particularly in geothermal energy production. By drilling precisely into geothermal reservoirs, operators can harness the Earth’s natural heat to generate electricity. This application highlights the role of directional drilling in supporting the transition to sustainable energy sources.

Environmental Remediation

Directional drilling is a powerful tool for environmental remediation, allowing operators to drill to specific locations to clean up contaminated sites. For example, it can be used to inject treatment solutions into polluted groundwater or to extract hazardous materials from underground storage tanks. This targeted approach minimizes surface disruption and ensures effective remediation.

Advantages of Directional Drilling

Directional drilling offers numerous advantages over traditional vertical drilling. One of its most significant benefits is increased efficiency and cost-effectiveness. By accessing multiple reservoirs from a single site, operators can reduce the need for additional infrastructure and lower overall project costs.

Another key advantage is its reduced environmental impact. Directional drilling minimizes surface disruption, making it ideal for use in sensitive areas. It also allows for the extraction of resources from hard-to-reach or unconventional reservoirs, expanding the scope of viable projects.

Safety is another critical benefit. By reducing the need for multiple drilling sites and minimizing surface activity, directional drilling enhances safety for workers and surrounding communities. Its precision and efficiency also reduce the risk of accidents and equipment failures.

Challenges and Limitations of Directional Drilling

Despite its many advantages, directional drilling is not without challenges. Maintaining accuracy in complex subsurface environments requires advanced technology and skilled operators. Equipment wear and tear is another concern, as the tools used in directional drilling are subjected to extreme conditions.

The high initial costs of directional drilling can also be a barrier, particularly for smaller operators. Specialized equipment and expertise are required, making it a resource-intensive process. Additionally, environmental concerns, such as the potential for groundwater contamination, must be carefully managed to ensure sustainable operations.

Innovations and Future Trends in Directional Drilling

The future of directional drilling is being shaped by emerging technologies and innovations. Automation and AI-driven drilling systems are streamlining operations, reducing costs, and improving accuracy. Advances in real-time data monitoring and analytics are also enhancing precision, allowing operators to make informed decisions on the fly.

Directional drilling is playing a crucial role in the transition to renewable energy sources. Its applications in geothermal energy and carbon capture and storage highlight its potential to support sustainable development. As technology continues to evolve, directional drilling will remain at the forefront of innovation in energy and infrastructure.

How to Choose the Right Directional Drilling Service Provider

Selecting the right directional drilling service provider is critical to the success of any project. Key factors to consider include the provider’s experience, technology, and safety record. Look for companies with a proven track record in similar projects and a commitment to using state-of-the-art equipment.

When evaluating potential providers, ask questions about their expertise, project management capabilities, and approach to safety and environmental protection. It’s also important to ensure that the provider’s capabilities align with your project requirements, from technical specifications to budget constraints.

You might also like

Book a Service Today

We will get back to you as soon as possible

Please try again later

Do You Need Emergency Plumbing Services?

We are dedicated to giving your fast, friendly and reliable service. We offer services every day of the week, at the time that's best for you.

All Rights Reserved | Root 24 Hours, Inc. | Powered by Beholder Agency