Trenchless Pipe Repair

Introduction to Pipe Repair without digging a Trench

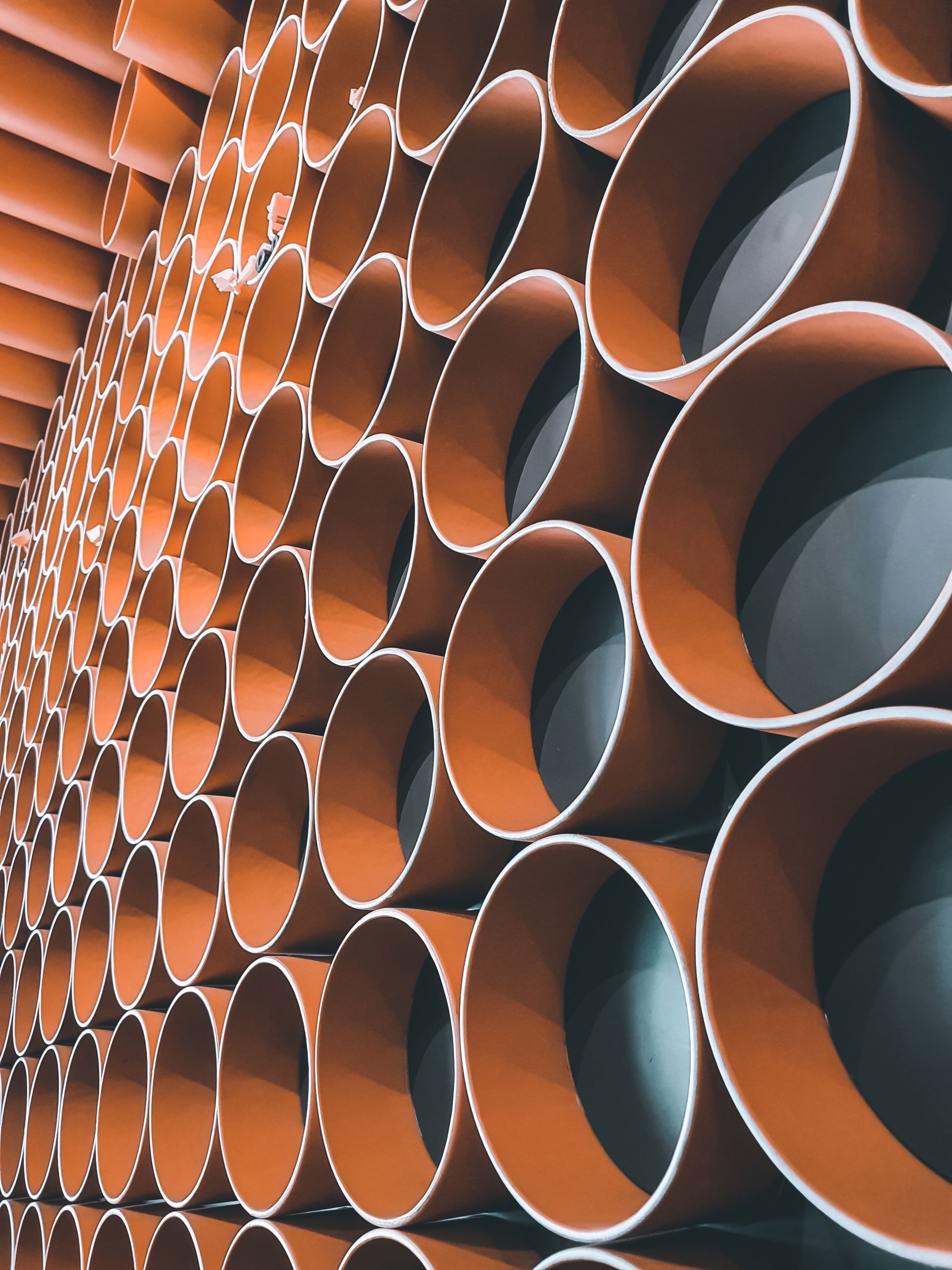

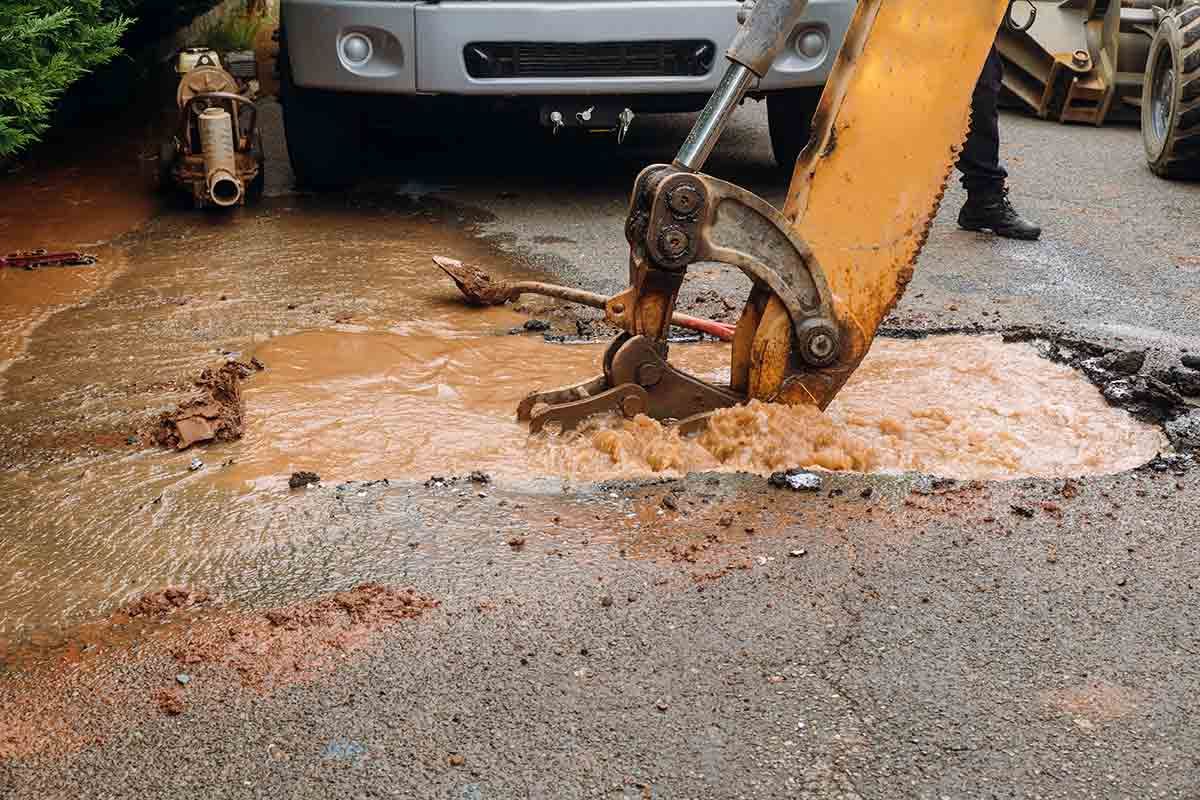

Trenchless repair transforms underground infrastructure maintenance, offering a minimal-disruption alternative to traditional methods. This technology, crucial in the construction and civil engineering industries, minimizes ecological impact and surface disturbances.

The global market for trenchless repairs, valued at approximately USD 1.54 billion in 2020, is projected to grow steadily, reaching about USD 2.26 billion by 2026. This reflects the increasing adoption of techniques like Cured-In-Place Pipe (CIPP) and pipe bursting, which save time, reduce costs, and extend infrastructure longevity without extensive excavation.

Get a quote

What is Trenchless Pipe Repair?

This form of pipe repair is a modern method of repairing and replacing damaged water pipes and fixing sewer problems without extensive excavation. This innovative approach allows for the repair of pipelines by making only minimal access points, significantly reducing the disruption and landscape damage associated with traditional methods.

Benefits of Trenchless Technology

1. Quicker Completion: Trenchless repair works are typically faster than traditional methods, reducing the time your property is disrupted.

2. Cost-Effectiveness: It generally costs less due to fewer labor requirements and minimal surface restoration needs, ensuring your financial security.

3. Less Invasive: Trenchless technology avoids extensive excavation, preserving your property’s landscape and structural integrity.

4. Environmental Benefits: This method lowers the environmental impact by reducing soil displacement and minimizing carbon emissions.

5. Durability: Trenchless repairs are long-lasting, often extending the life of the infrastructure with durable materials and advanced techniques.

6. Versatility: It can be applied in various settings, including residential, commercial, and municipal infrastructures.

7. Safety: Less excavation reduces the risk of damaging utility lines or causing other hazards on-site.

Our Trenchless Repair Services

Pipe Lining Solutions

Cured-in-Place Pipe (CIPP)

Cured-in-place pipe (CIPP) is a trenchless technique to rehabilitate existing pipelines. The process entails inserting a felt tube saturated with resin into the damaged pipe and then curing it using UV light, steam, or hot water to solidify the resin.

This results in creating a new, seamless, and corrosion-resistant pipe inside the original one, effectively renewing the pipe system without excavation. This method is particularly suitable for repairing pipes that have been damaged by cracks, breaks, and root intrusion, offering a cost-effective and durable solution.

Epoxy Pipe Coating

Epoxy pipe coating is an advanced repair technique for spraying a safe, non-toxic epoxy resin inside the damaged pipes. This coating seals all existing cracks and corrosion and prevents future issues by creating a smooth, seamless inner surface.

This method enhances the flow and significantly extends the pipes’ life. It’s particularly effective for smaller-diameter pipes and when excavation is impractical or too costly.

Pipe Bursting Services

Hydraulic Pipe Bursting

Hydraulic pipe bursting is a dynamic trenchless replacement method. Powerful hydraulic equipment fractures the old, damaged pipe and pushes it outward while a new pipe is pulled into place simultaneously.

This method effectively replaces brittle pipes like clay, concrete, or PVC with more durable materials like HDPE. It’s suitable for larger-scale municipal projects and areas where minimal surface disruption is a priority.

Static Pipe Bursting

Static pipe bursting, like hydraulic bursting, involves replacing old pipelines but uses a powerful static pulling device instead of hydraulics. This method is well-suited to heavy-duty pipe materials and challenging environmental conditions, ensuring a reliable replacement with new, long-lasting pipes with minimal impact on the surrounding area.

Slip Lining

Slip lining is one of the oldest trenchless rehabilitation methods. It involves installing a smaller “carrier pipe” into a larger “host pipe” and then filling the annular space between the two with grouting material to stabilize the structure. This method is particularly useful for repairing large-diameter mains and can be performed under live conditions, which minimizes service interruptions.

The Trenchless Repair Process

Initial

Inspection

We start with a detailed video camera inspection to assess the condition of your pipes and identify the exact locations and nature of the damage.

Cleaning and

Preparation

The pipes are thoroughly cleaned using high-pressure jetting or mechanical methods to prepare them for the lining process.

Repair and

Installation

The chosen trenchless method is then implemented to repair or replace the damaged sections of piping efficiently.

Final Inspection

and Testing

After installation, a final camera inspection and testing are conducted to ensure the integrity and functionality of the repaired pipes.

Why Choose Root 24 for Trenchless Sewer Line Repair?

Experienced Technicians

Our team comprises industry-certified professionals with extensive knowledge and experience in trenchless repair techniques.

Minimal Disruption

Our methods ensure minimal disruption to your property and daily activities, with most repairs completed in a day or less.

Long-Lasting Solutions

We use high-quality materials and state-of-the-art techniques to provide durable and long-lasting repairs.

Trenchless Repair vs. Traditional Methods

Cost-Effectiveness

Trenchless methods are generally more cost-effective than traditional excavation for several reasons.

First, they require significantly fewer workers and less heavy equipment. Second, there is minimal need for landscape restoration, as the ground surface is largely undisturbed. This translates to lower overall costs from reduced labor, minimal disruption, and shortened project duration.

Additionally, the long-term durability of trenchless repairs means less frequent repairs and maintenance, providing substantial cost savings over time.

Time Efficiency

Trenchless pipe repair technologies are highly efficient and capable of completing projects in a fraction of the time required by traditional methods.

Traditional excavation often involves lengthy processes of digging, pipe fixing or replacement, and restoring the site, which can take days or weeks.

In contrast, trenchless techniques, such as CIPP lining or pipe bursting, can often be completed in a few hours to a day. This rapid turnaround minimizes inconvenience and reduces the costs associated with prolonged construction activities.

Environmental Impact

Trenchless technology is more environmentally friendly than traditional pipe repair methods.

By avoiding extensive digging, trenchless methods reduce the disturbance to the local ecosystem, preserve the existing landscaping, and limit the amount of debris and pollutants that typically result from excavation.

Furthermore, the reduced use of heavy machinery means lower carbon emissions. These factors make trenchless repairs ideal for environmentally sensitive areas or urban settings where disruption must be minimized.

Why Choose Root 24 for Trenchless Sewer Line Repair?

Sewer Line Cracks

If not addressed promptly, sewer line cracks are a common issue that can lead to significant water loss, ground contamination, and increased costs.

Trenchless repair methods, such as CIPP lining, effectively seal these cracks with a resin that hardens to form a pipe within a pipe, reinforcing the structure without the need to replace the entire segment.

This method not only fixes the leaks but also improves the pipe’s structural integrity, preventing future problems.

Corrosion and Aging Pipes

Over time, pipes, particularly metal ones, can deteriorate due to corrosion.

Trenchless rehab methods like epoxy lining can give these old pipes a new lease on life. The epoxy forms a corrosion-resistant barrier inside the existing pipe, preventing further decay and leaks without replacing the pipe entirely.

This is especially beneficial for historic or older neighborhoods, where extensive excavation could damage the community’s character and infrastructure.

Root Intrusion

Root intrusion from trees seeking moisture can cause significant damage to sewer lines, leading to blockages, reduced flow, and, eventually, pipe failure.

Trenchless repair techniques, such as CIPP lining and pipe bursting, allow us to clear the roots and repair the damage without excavating the affected area.

This solves the immediate problem and strengthens the pipe against future invasions, ensuring a more durable solution with less maintenance required.

Frequently Ask Questions

As a leading plumbing company that addresses your drain service needs, we’ve compiled answers to some common drain system concerns. Remember, our expert team is just a call away for professional assistance with any plumbing issue.

Contact us online for a quote

How much does trenchless pipe repair cost?

The cost can vary based on the extent of damage, pipe material, and the specific repair method used. We offer competitive pricing and detailed quotes tailored to your situation.

Is Trenchless Repair Suitable for All Pipes?

While trenchless repair is versatile, it is not suitable for all conditions. Severely collapsed pipes might require partial excavation. Our initial inspection helps determine the best approach.

How Long Does Trenchless Repair Last?

Trenchless pipe repairs can last as long as new pipes, often over 50 years, depending on the material and environment.

What Are the Limitations of Trenchless Technology?

The main limitations include the existing pipe’s diameter and the severity of damage. Extremely narrow or severely collapsed pipes may not be suitable for certain trenchless techniques.